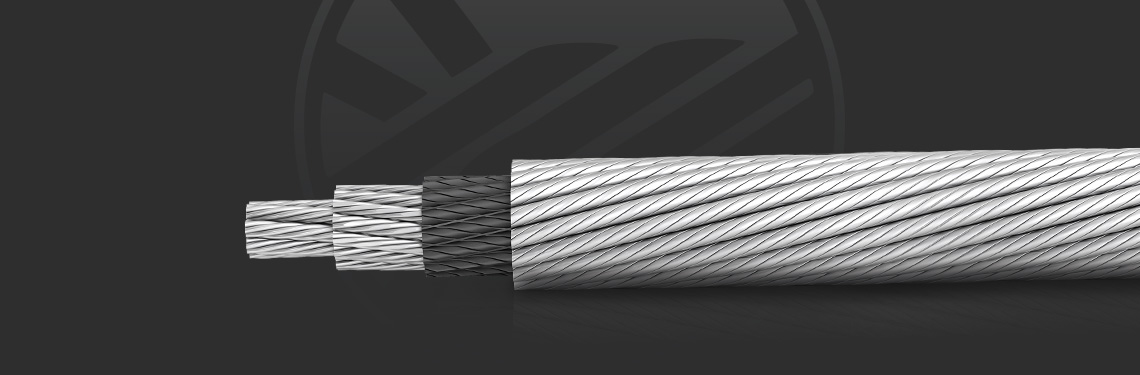

FORCEPAC COMPACTION TECHNIQUE

In multi-layer systems, the reason for wire rope discard is often not fatigue but an effect called drum crushing. Drum crushing occurs in the cross-over zones of the drum because of high line pulls, high spooling angles or interlocking wires of adjacent drum wraps. Although fatigue-wise the wire rope has not reached the end of its service life, it has to be discarded due to crushed wires and strands. While HiPac compacted ropes provide a high resistance, some crane systems require a more advanced solution.

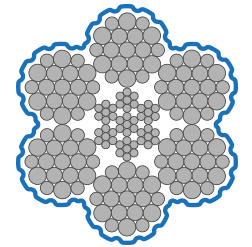

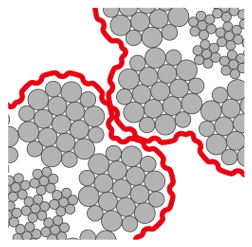

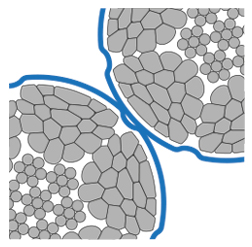

WDI has developed a solution against drum crushing in multi-layer systems called ForcePac compaction. ForcePac compacted wire rope provides a smooth and near-round circumference when the drum is spooling in. Wires or strands of the adjacent wrap cannot interlock anymore. Instead they glide off their neighbouring wrap into their predetermined position in the spooling package. This reduces the damage mechanism compared to conventional wire rope by 25-50%. ForcePac is available for both rotation-resistant and non rotation-resistant wire rope.

less wire interlocking

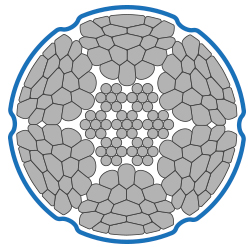

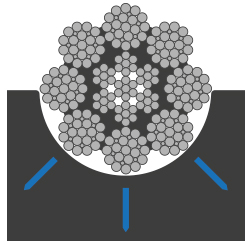

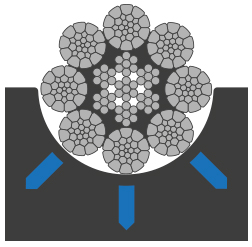

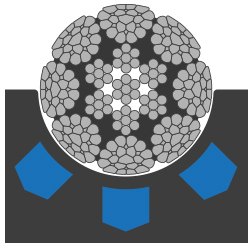

An added benefit is the optimum pressure distribution in the sheave groove. An uncompacted rope is prone to high abrasion when running over sheaves due to only punctual contact of the crown wires with the sheave groove. ForcePac compaction provides the maximum support area. Abrasion is greatly reduced and both rope and sheave service life is significantly improved. Especially in systems with low design factors, ForcePac enabled wire rope can give economic benefits over conventional constructions.

ForcePac compacted ropes are also highly suited for applications in dirty or dusty environments such as forestry. Being dragged through mud, bent around trees and pulled over rock, conventional wire rope is prone to inner destruction by penetrating particles. With both strand and wire gaps closed, PYTHON logging ropes provide a very round and smooth surface. A dedicated catalogue from Europe’s market leader in forestry wire rope is available.